Joining aluminium to steel

Joining aluminium to steel

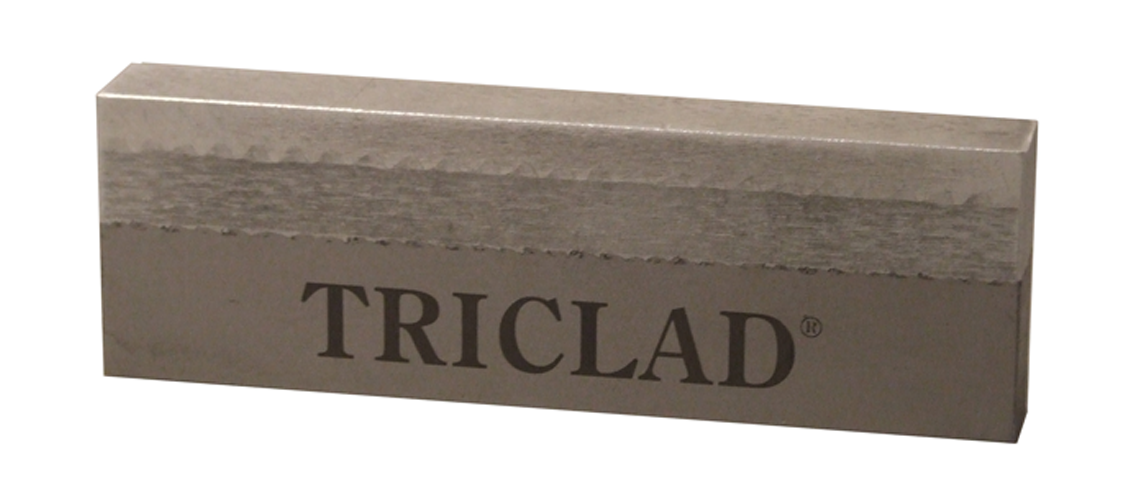

This website is intended to look at TriClad’s structural transition joints (STJ) as marketed by Merrem & la Porte in many countries around the world. Furthermore, this website gives an insight into the history, applications and technical aspects of these joints. Also practical advice regarding their use is incorporated in this website.

Firstly, what is a transition joint, what is it used for, and how does Merrem & la Porte come to market the product ? Transition joints are bimetallic strips or pads used to facilitate the joining of dissimilar metals by welding. Particularly where those metals cannot be joined by conventional welding processes, and where, if mechanical joining techniques are used, corrosion sets in after a relatively short service life. Their uses are generally found in marine construction, but are equally applicable in other industries where a permanent, maintenance free joint between aluminium and steel is called for.

Typical applications of structural transition joints

Typical applications of structural transition joints

Increasingly, aluminium is being used in shipbuilding to reduce weight. However, on grounds of cost and durability, it is not normally used for the whole of the hull, which may be mainly steel. With aluminium being used to a greater or lesser degree for structures above the waterline to reduce overall deadweight or to lower the centre of gravity, thus improving roll performance. This is paticularly beneficial on RO-RO ferries.

Typical applications of structural transition joints are to:

- Join aluminium superstructures to steel decks.

- Join aluminium decks (or even bulkheads) to steel hulls.

- Fit shelter decks to steel fishing boats.

- Retrofit “containers” of electronic equipment to steel decks of warships during refits.

- Add additional accommodation to existing vessels (these can be prefabricated).

- Fit any other components, such as pillars, partitions, etc., where a permanent joint is required between steel or stainless steal and aluminium.

They can even be used to:

- Fit steel components to aluminium hulls (engine mounts in high speed catamarans, davits, etc.).

- Repair or strengthen corroded mechanical gasketed joints on ships where transition joints were not originally specified (even to make these watertight by welding over the joint face).

- Provide a wear resistant keel on beach launched aluminium vessels.

Other uses are to:

- Fit helidecks to ships or oil rigs.

- Fix aluminium walkways or accommodation modules on oil rigs.

Additionally, there may be potential applications in road- and rail vehicles or even in civil engineering and chemical plants.Specialised joints, incorporating an extra layer, in this case titanium, can be used to attach aluminium cryotanks to steel decks

What are the advantages of using TriClad as opposed to “traditional” methods of joining?

TriClad® is:

- Permanent, maintenance free, fit and forget

- Can be installed by one operative

- Continuous joint, even stress distribution

- Rigorously tested approved product

- Watertight. Any corrosion self extinguishing

Traditional methode of joining:

- Generally require use of bolts or rivets, plus gaskets. Can work loose, due to flexing of the hull, creating gaps in which corrosion develops. Rivet or bolts needs to be insulated from aluminium.

- Generally, two operatives necessary

- Rivets/bolts give uneven stress

- Difficult to asses quality of joints

- Tend to leak

Merrem & la Porte and TriClad

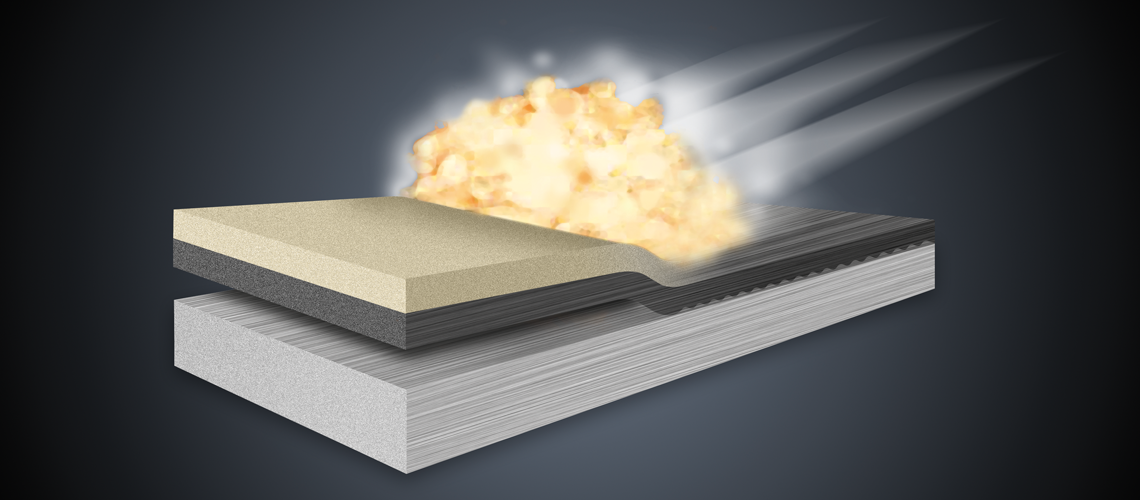

Merrem & la Porte's involvement in the marketing of al/st transition joints stems from having been originally appointed as agents in the Benelux countries for explosion bonded plates manufactured by NobelClad, France subsidiary of Dynamic Materials Corporation (DMC). When it was perceived that, the Netherlands being the shipbuilding nation that they were and still are, there should be a significant and growing market in Holland for STJ’s, Merrem & la Porte was asked to trial market the product. The sales were so successful that, it was a logical step to increasingly source STJ’s for world markets. Selling either direct, or through agents / distributors in close contact with thenational shipbuilding industry, Merrem & la Porte has since been the global and exclusive outlet for DMC produced STJ’s.

Read more about TriClad:

Aluminium steel welding | What is a structural transition joint? | What is explosive bonding? | What is explosion welding? | What is explosive cladding? | The application of TriClad in the marine industry | Welding parameters: general guidelines | Fabrication guidlines | Corrosion resistance | What is TriClad? | General background of explosion cladding | Joining aluminium to steel | Welding aluminium to steel: TriClad