TriClad®: aluminium - steel transition joints for shipbuilding and the marine industry

TriClad®: aluminium - steel transition joints for shipbuilding and the marine industry

TriClad® supplies connection strips for luxury yachts and the marine industry. This structural transition joint is used in boats made of steel and aluminium such as yachts and in ships for defence.

Shipbuilding and welding aluminium to steel

TriClad® is used in the construction of aluminum-steel vessels, including luxury yacht building and in marine vessels. Aluminium-steel connecting strips are needed in the construction of these ships, because aluminium and steel cannot be connected by a hot welding process. TriClad® always has sufficient material in stock to guarantee the shortest possible delivery time. TriClad® is supplied as standard with a Lloyds 3.2 certificate.

TriClad®: the structural transition joint for shipbuilding

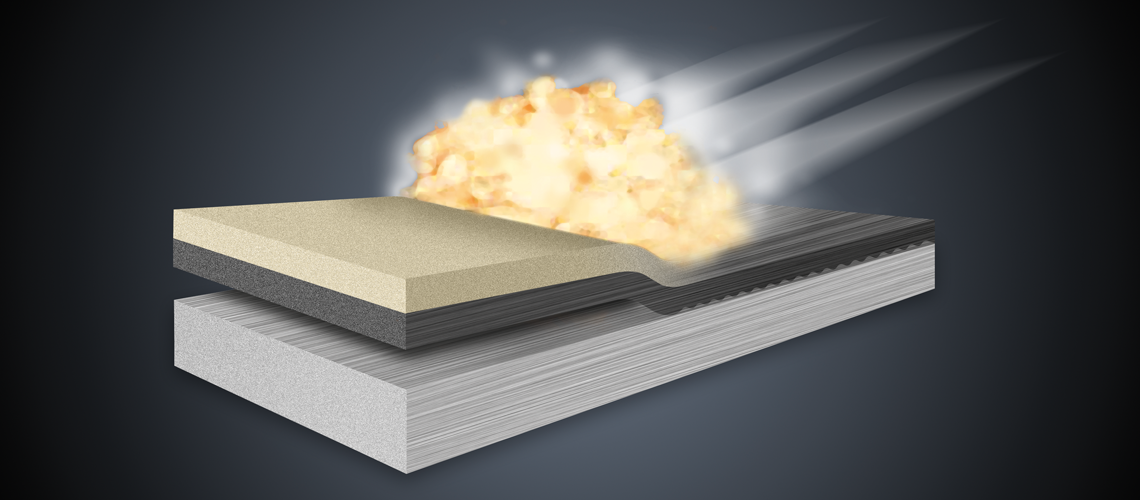

TriClad® is a connecting strip or structural transition joint that connects aluminium to steel: an aluminium-steel transition joint. This product is made by NobelClad. NobelClad is the market leader in explosion welding.

Explosion cladding of explosion bonding for shipbuilding

Cladded metal are two metals that are 'welded' on top of each other. In the case of explosion cladding or explosion boding, welding is not really the right word: the two metals are pressed together by an explosion. The pressure created by the explosion releases heat. This heat is sufficient to connect the two metals. In shipbuilding, explosion cladding or explosion bonding is often chosen because with 'normal' welding processes there is a high chance that corrosion will occur. Especially with large ships this is a very undesirable effect. Because clad material is produced with such great force, external influences (such as contaminants and oxygen) have little or no chance to act on this transition layer.

Why do we need to weld aluminium to steel in shipbuilding?

Cladded metals and structural transition joints are mainly found in the shipbuilding industry. A ship's hull is often made of steel, while the rest is often made of aluminium. The hull is made of steel because this material can withstand cold water better. By making the deck of lighter material (such as aluminium) the centre of gravity of the boat is lowered.

Read more about TriClad:

Product | Production | Advantages | Approach | Brochure | FAQ | Contact

Find out more about structural transition joints and TriClad:

About TriClad | General background of explosion cladding | TriClad's corrosion resistance | Welding aluminium to steel | Joining aluminium to steel | Aluminium steel welding | What is a structural transition joint | Structural transition joints: DetaCouple and TriClad | Explosion welding | Explosion bonding | Explosion cladding | The application of TriClad in the marine industry | TriClad plate in strips - cut on demand for you | TriClad for cruise ships | Yacht TriClad | Marine TriClad