About TriClad

About TriClad

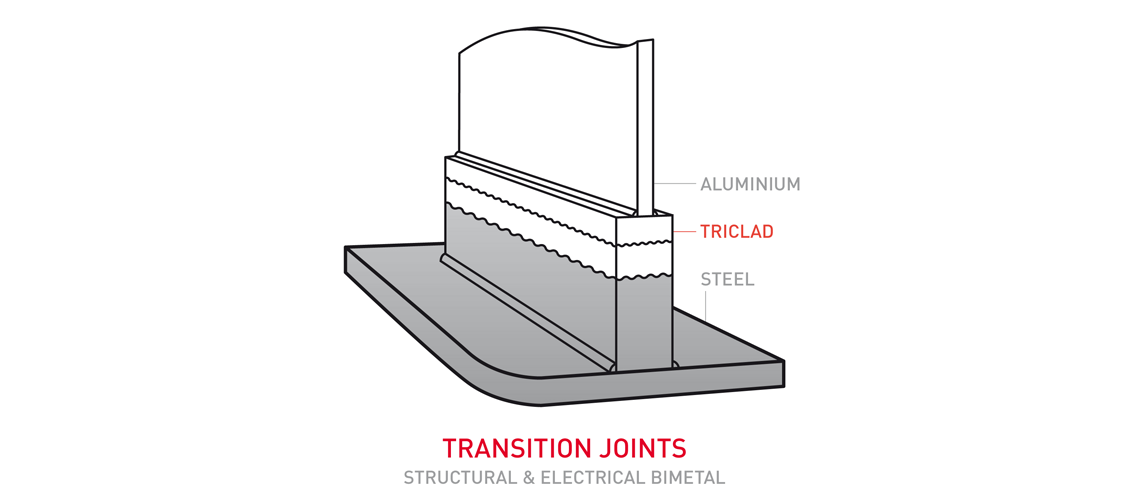

TriClad® is the tradename of Merrem & la Porte for aluminium/steel structural transition joint material. Structural transition joints (STJ’s) are used for joining aluminum to steel structures in shipbuilding industry, such as marine applications, naval applications, cruiseships, yachts and superyachts and defence industry.

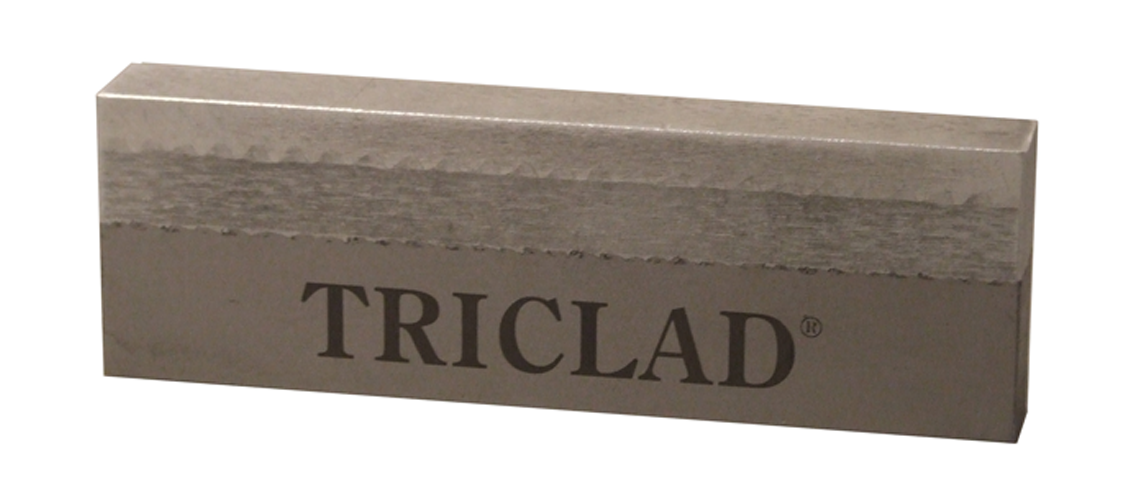

As indicated, TriClad® is a special clad, designed generally to facilitate the joining of marine grade aluminium structures to steel structures for shipbuilding industry. It is produced as a standard sized “parent plate” in the as clad size 1.5 x 4 meters , with a useable area of 1300 x 3800 millimeters from which strips or other shapes can be cut. The metal grades chosen are designed to be compatible with the commonly used marine grades of aluminium and steel. DMC NobelClad have standarised on the following grades and nominal metal thicknesses.

About TriClad

About TriClad

ASTM A516 Gr.55 / Aluminium 1050A/Aluminium 5086 *

- Thickness: 19 + 9.5 + 6 mm

- Shear strength: min 60 MPa / typical 94 MPa

- Tensile strength: min 76 MPa / typical 126 MPa

Shipbuilding steel Gr.D / Aluminium 1050A /Aluminium 5083

- Thickness: 15 + 3 + 10 mm and 20 + 3 + 10 mm

- Shear strength: min 70 MPa / typical 94 MPa

- Tensile strength: min 80 MPa / typical 181 MPa

ASTM A516 Gr.55 / Aluminium 1050A /Aluminium 5083

- Thickness: 10 + 5 + 4 mm

- Shear strength: min 60 MPa / typical 94 MPa

- Tensile strength: min 76 MPa / typical 126 MPa

TriClad’s availability

- Standard strip length 3800 mm

- Minimum strip width 10 mm

Commonly used strip widths carried in stock are 16 - 20 - 24 - 25 - 30 mm.

Up to the parent plate width of 1350 mm we can cut any requested strip width within a matter of days, if not available off the shelf. Cutting tolerances on strip width will usually be within +/- 1 mm per linear metre.

Additionally we can cut squares, rectangles, discs, or even complex shapes by our waterjet cutting facility. The latter two by means of a water jet which will minimize the need for finish machining.

Cutting processes vary. Strips and pads can be cut using band saws. Shapes can be cut by machining, or water jet, depending upon application and/or accuracy/finish required.

Mechanical properties of TriClad composition

The MIL-J-24445A specification, which TriClad ® conforms to, calls for the mentioned minimum properties in both the as-clad condition as well as after a simulated welding cycle (heat treatment 15 minutes, 315°C + Air cool). DMC NobelcCad will release parent plates on the basis of these criteria. However, typical values for TriClad ® are considerably higher. After simulated welding cycle: Through thickness tensile strength 120 MPa bond shear strength 88 MPa

First article testing for compliance with the MIL-J 24445A specification also included axial fatigue strength testing as well as tensile strength determination on welded specimens. Again all criteria were well met.

Rigorous quality procedures and regular authority verification have earned TriClad ® product / use approval from the following authorities:

- Lloyd’s Register of Shipping (LRS)

- Det Norske Veritas - Germanischer Lloyd (DNV GL)

- Bureau Veritas (BV)

- American Bureau of Shipping (ABS)

- Registro Italiano Navale (RINA)

Non-standard TriClad

It has been at the request of our customers, and after extensive research and development work, that we have developed other variants on the standard TriClad material using titanium interlayer.

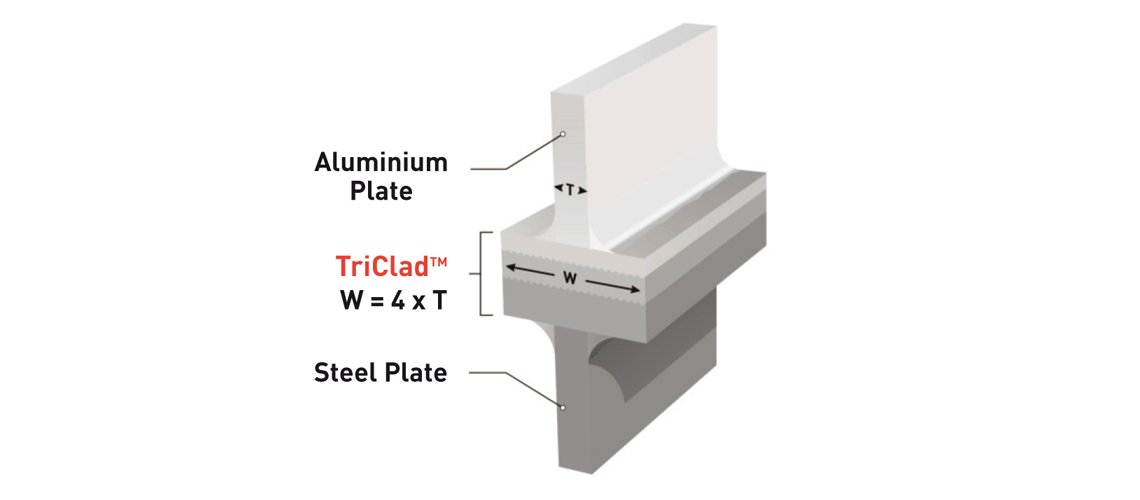

The incorporation of a titanium interlayer in lieu of CP Aluminium will allow the use of narrower marine transition joint strip then what the “4 times thumb rule” would call for. This obviously is due to the superior mechanical characteristics of titanium as compared to the Aluminium 1050 that is used in standard TriClad version.

Titanium interlayered TriClad

The Titanium interlayered TriClad version with aluminium is made up of:19 mm Steel ASTM A516 Grade 551.0 - 1.5 mm Titanium ASTM B265 Grade 110 mm aluminium 3003

Stainless Steel TriClad

This product enables you to weld stainless steel components such as anchor hawse holes, bollards, railings, stairs, etc. to an aluminium deck.The stainless steel TriClad version is made up of: 19 mm stainless steel AISI 316L1.0 - 1.5 mm titanium ASTM B265 Grade 110 mm aluminium 3003. Although typical tests show significantly higher results, we suggest to use the following minimum values of the composite for design purposes for both stainless and titanium interlayered combination: Tensile strength 100 MPa shear strength 55 MPa. In case any additional information is required, you can contact our office in The Netherlands.

Read more about TriClad:

Aluminium steel welding | What is a structural transition joint? | What is explosive bonding? | What is explosion welding? | What is explosive cladding? | The application of TriClad in the marine industry | Welding parameters: general guidelines | Fabrication guidlines | Corrosion resistance | What is TriClad? | General background of explosion cladding | Joining aluminium to steel | Welding aluminium to steel: TriClad