What is explosion welding?

What is explosion welding?

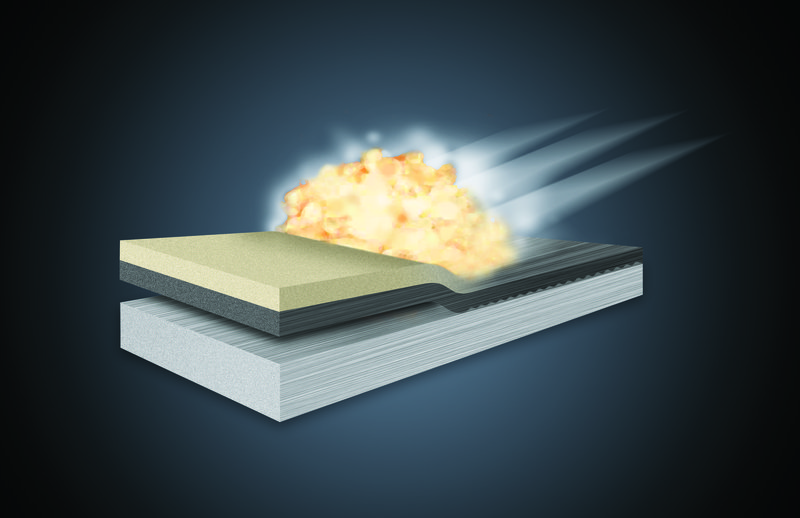

Explosion welding is a joining technique that uses the merging principle to join two materials together. In this process, welding is carried out by accelerating a very high speed component. This is done with the aid of chemical explosives. The explosion weld is completed in milliseconds, eliminating bulk heating and metal weakening.

Did you know that explosion welding is also called shock wave welding? It is therefore quite a violent process. Only specialised companies can carry out this welding.

Explosion welding is used to connect two dissimilar metals. In shipbuilding, it is a requirement that the mechanical, electrical and corrosion properties of both metals are preserved. Explosion welding makes this possible. Explosion welding is a solid state welding process that uses precision explosions.

How does explosion welding work?

How does explosion welding work?

The parts that need to be connected are placed at a certain angle to each other. Explosive material is applied to the sheet metal. This is done evenly. A shock wave pushes one metal against another. This is done at a speed of about 100 m/s. During this process, an energy is released that is converted into heat. This effect causes the formation of a local plasma jet. It blows away oxides and makes a thin layer of both metals plastic. The pressure on both metals pushes the atoms together and creates a bond.

The history of explosion welding

Explosion welding is a relatively new process. Although its use became more popular only in the years after the Second World War, the process was discovered in the First World War.

In contrast to many other forms of welding, explosion welding was therefore only developed after the Second World War. In fact, this form of welding was discovered by accident. Pieces of shrapnel stuck to the armour. It was seen that these pieces were not only embedded, but were actually simply welded to the metal. Unlike other welding methods, no extreme heat was used. For example, it was discovered that explosives (in this case the shrapnel) can also be welded. The process was imitated and perfected in laboratories until it was used in real welding situations in the 1960s.

Read more about TriClad®:

Aluminium steel welding | What is a structural transition joint? | What is explosive bonding? | What is explosion welding? | What is explosive cladding? | The application of TriClad in the marine industry | Welding parameters: general guidelines | Fabrication guidlines | Corrosion resistance | What is TriClad? | General background of explosion cladding | Joining aluminium to steel | Welding aluminium to steel: TriClad