What is explosive cladding?

What is explosive cladding?

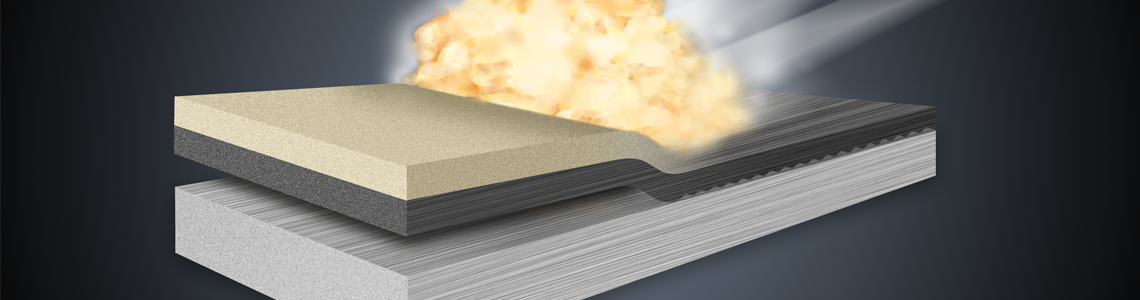

Explosive cladding is also known as explosion welding. So, explosive cladding or explosive welding is the bonding of two dissimilar metals with the use of explosives. The explosive clad is achieved through a high-velocity oblique impact between two different metals.

The explosive cladding / explosion cladding process

The high-velocity impact produces enough energy to dynamically hydrostream the impacting metal surfaces. The metal surfaces are compressed under high pressure from the explosion and an atomistic adhesion between the different metals will be achieved. This provides solid bonding.

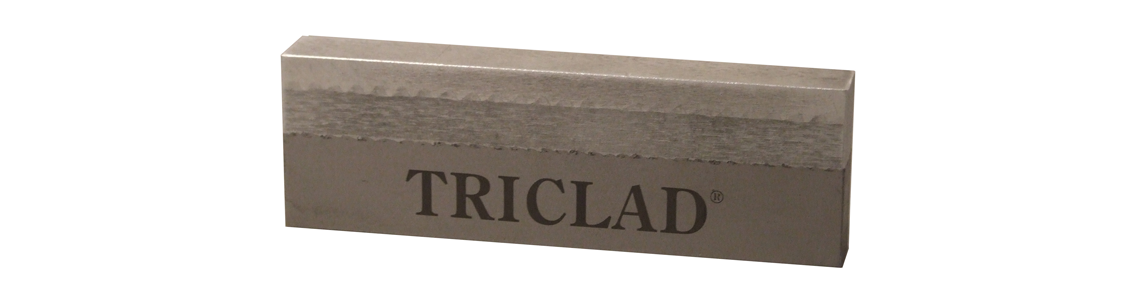

Explosive cladding is a cold pressure weld process. This method is used to weld metals that can’t be welded by conventional processes. An example of two metals that can not be welded is aluminium-steel, a combination that is commonly used in shipbuilding. With TriClad, shipbuilders have a transition joint that welds aluminium to steel.

Explosion cladding operation

Explosion cladding operation

As the process uses a large quantity of specially produced explosive, the actual cladding operation is generally carried out in a remote place.

The stages of explosion cladding

- The two metals (aluminium and steel) to be joined are first prepared for cladding.

- The faces are cleaned and the plates set up one above the other with a pre-determined gap. The gap and gapping method vary with the metal combination and metal thicknesses. Generally, the thinner metal (the cladder) is uppermost and slightly larger than the base metal. The overhang is again determined by the thicknesses of the metals. As the gap is critical, it is important that the plates are flat (generally better than 3mm/m).

- The plates are placed on a firm sand base, such that they are evenly supported, care being taken to ensure that no foreign material enters the gap.

- A frame is positioned round the periphery of the cladder, the depth of which is designed to ensure that the quantity of explosive (the loading) per unit area, is consistent with the loading prescribed for the metal combination and the cladder thickness. The explosive loading ensures that the cladder is accelerated to the optimum speed for bonding, and the velocity of the explosion front across the plate ensures that the angle between the cladder and the base is the optimum for the metals.

- The extremely high pressure generated at the point where the metals initially meet vaporises the surface contaminants (oxides) which are ejected, thus producing the molecular bond between the two virgin surfaces.

- The layer of metal removed is only microns thick. Some very localised work hardening occurs, but in general the properties of the two metals remain unchanged.

- The metal temperature after cladding is such that you can place your hand on the surface. In most cases the interface is slightly wavy; the amplitude again varies with the metals and is most pronounced with aluminium/steel.

- In a very limited number of cases the bond may contain some (harmless) intermetallics. In an even smaller number of combinations the bond properties may be improved with a low temperature heat treatment. Whilst in most cases, the bond between the two metals is consistent, there are some where the metal structures differ considerably. The bond quality can then be improved by using an interlayer.

Read more about TriClad:

Product | Production | Advantages | Approach | Brochure | FAQ | Contact

Find out more about structural transition joints and TriClad:

About TriClad | General background of explosion cladding | TriClad's corrosion resistance | Welding aluminium to steel | Joining aluminium to steel | Aluminium steel welding | What is a structural transition joint | Structural transition joints: DetaCouple and TriClad | Explosion welding | Explosion bonding | Explosion cladding | The application of TriClad in the marine industry | TriClad plate in strips - cut on demand for you | TriClad for cruise ships | Yacht TriClad | Marine TriClad